| Availability: | |

|---|---|

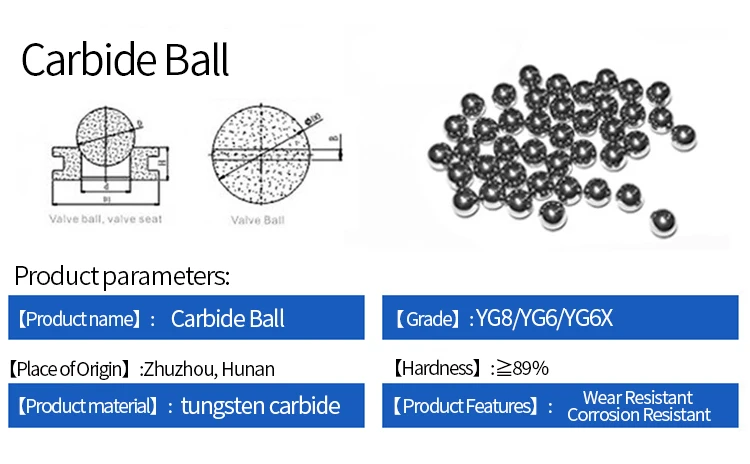

Tungsten carbide ball

Tungsten carbide ball from Zhuzhou Jinxin is extremely hard. The manufacturing technique makes tungsten carbide ball substantially more expensive than other materials, but practically inert. Their relative inertness makes them extremely resistant to interaction with various liquids and alloys. Tungsten carbide balls can be found in heavy machinery applications, since they are much stronger than stainless steel or chrome. Particularly, tungsten carbide ball has been used in industrial sprayers to regulate the flow of fertilizers or pesticides to crops.

Tungsten carbide balls are ideal for applications where extreme hardness must be accompanied by high resistance to wear and impact. They are well-suited to elevated temperatures, corrosion, humidity, abrasion, and poor lubrication conditions.titanium ballThe balls are made from 100% virgin tungsten carbide material.

This type of alloy ball is usually manufactured through a powder metallurgy process and sintered at high temperatures and pressures. Due to its high hardness, it can maintain wear resistance for a longer period of time in harsh working environments. Generally speaking, hard tungsten carbide alloy spheres will be much harder than ordinary steel spheres.

When using hard tungsten carbide alloy balls, care needs to be taken to avoid collision and damage, especially in the process of using to minimise the impact force. In addition, care should be taken to prevent contact with corrosive substances and to keep its surface smooth and intact. In the process of installation and use, it is also necessary to take appropriate protective measures according to the product specifications and the requirements of the use environment.

Tungsten carbide ball size list

Model/Item | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

| Ball-D +0.020/-0.010 (+0.51/-0.25) | 15.88 (0.625in) | 19.05 (0.75in) | 23.83 (0.938in) | 28.58 (1.125in) | 31.75 (1.25in) | 34.93 (1.375in) | 42.88 (1.688in) | 57.15 (2.25in) |

| Seat-ID ± 0.050 (± 1.27) | 11.68 (0.46in) | 13.97 (0.55in) | 17.02 (0.67in) | 20.96 (0.825in) | 24.38 (0.96in) | 26.92 (1.06in) | 33.27 (1.31in) | 43.18 (1.7in) |

| Seat-OD +0.000/-0.005 (+0.00/-0.13) | 20.14 (0.793in) | 23.32 (0.918in) | 29.67 (1.168in) | 35.26 (1.388in) | 37.54 (1.478in) | 43.69 (1.72in) | 51.05 (2.01in) | 78.03 (3.072in) |

| Seat-H +0.020/-0.010 (+0.51/-0.25) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 19.05 (0.750in) |

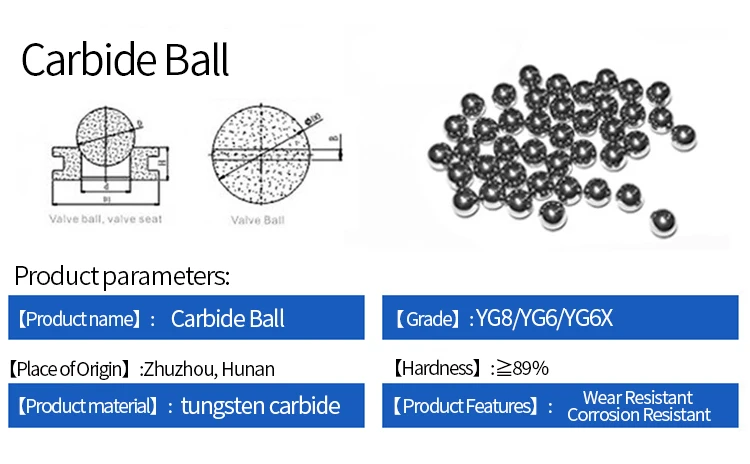

Tungsten carbide ball

Tungsten carbide ball from Zhuzhou Jinxin is extremely hard. The manufacturing technique makes tungsten carbide ball substantially more expensive than other materials, but practically inert. Their relative inertness makes them extremely resistant to interaction with various liquids and alloys. Tungsten carbide balls can be found in heavy machinery applications, since they are much stronger than stainless steel or chrome. Particularly, tungsten carbide ball has been used in industrial sprayers to regulate the flow of fertilizers or pesticides to crops.

Tungsten carbide balls are ideal for applications where extreme hardness must be accompanied by high resistance to wear and impact. They are well-suited to elevated temperatures, corrosion, humidity, abrasion, and poor lubrication conditions.titanium ballThe balls are made from 100% virgin tungsten carbide material.

This type of alloy ball is usually manufactured through a powder metallurgy process and sintered at high temperatures and pressures. Due to its high hardness, it can maintain wear resistance for a longer period of time in harsh working environments. Generally speaking, hard tungsten carbide alloy spheres will be much harder than ordinary steel spheres.

When using hard tungsten carbide alloy balls, care needs to be taken to avoid collision and damage, especially in the process of using to minimise the impact force. In addition, care should be taken to prevent contact with corrosive substances and to keep its surface smooth and intact. In the process of installation and use, it is also necessary to take appropriate protective measures according to the product specifications and the requirements of the use environment.

Tungsten carbide ball size list

Model/Item | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

| Ball-D +0.020/-0.010 (+0.51/-0.25) | 15.88 (0.625in) | 19.05 (0.75in) | 23.83 (0.938in) | 28.58 (1.125in) | 31.75 (1.25in) | 34.93 (1.375in) | 42.88 (1.688in) | 57.15 (2.25in) |

| Seat-ID ± 0.050 (± 1.27) | 11.68 (0.46in) | 13.97 (0.55in) | 17.02 (0.67in) | 20.96 (0.825in) | 24.38 (0.96in) | 26.92 (1.06in) | 33.27 (1.31in) | 43.18 (1.7in) |

| Seat-OD +0.000/-0.005 (+0.00/-0.13) | 20.14 (0.793in) | 23.32 (0.918in) | 29.67 (1.168in) | 35.26 (1.388in) | 37.54 (1.478in) | 43.69 (1.72in) | 51.05 (2.01in) | 78.03 (3.072in) |

| Seat-H +0.020/-0.010 (+0.51/-0.25) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 19.05 (0.750in) |